DRILLING SOLUTIONS

Reserve Circulation Grade and Control Drilling

Using reverse circulation drilling techniques and advanced sample splitting and recovery systems our grade control drills can provide samples helpful to differentiate ore and waste rock maximizing the profitability of your mining operations.

Our crews are focused on being productive, but not at the cost of poor sample quality. We provide dedicated supervision to ensure that communications are frequent with our clients and crews are well supported in the execution of the work. Our modern equipment is setup to deliver safe and productive outcomes. Our crews work safely and understand that a safe operation is a productive one.

We have a highly specialized fleet, the first in Africa.

- Altas Copco D-65 smart roc

- Amart ROC D65

- Splitters

Surface Manager, Rockma, Roc Manager and Certiq System

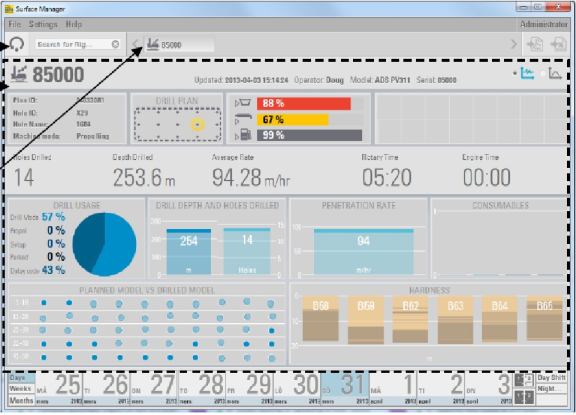

Surface Manager dashboard

Surface manager allows one to measure various parameters during drilling and can be accesssed in real time through the certiq telematics system.Roc Manager

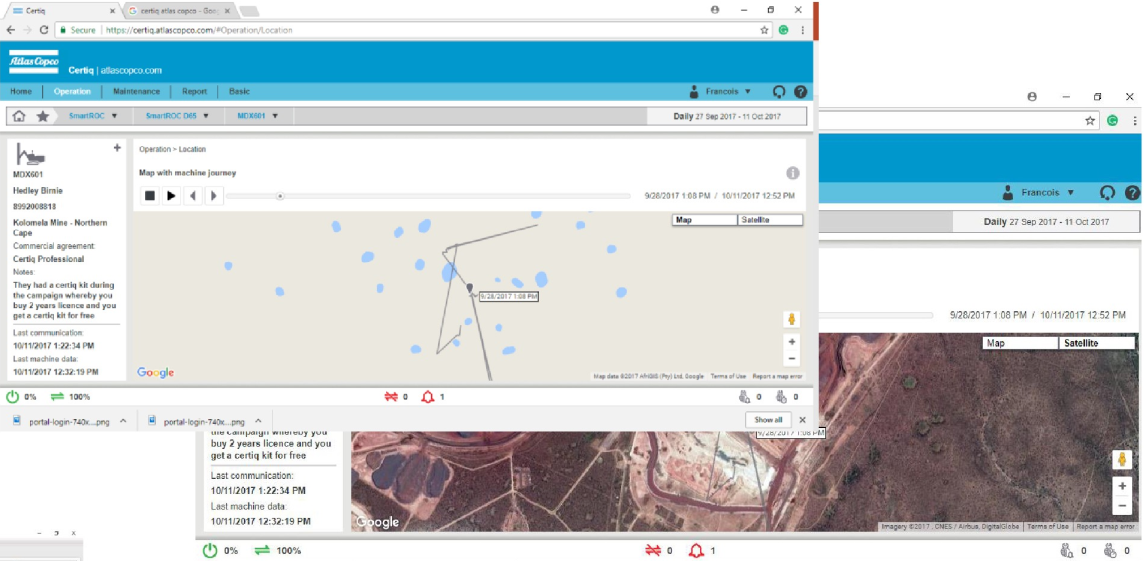

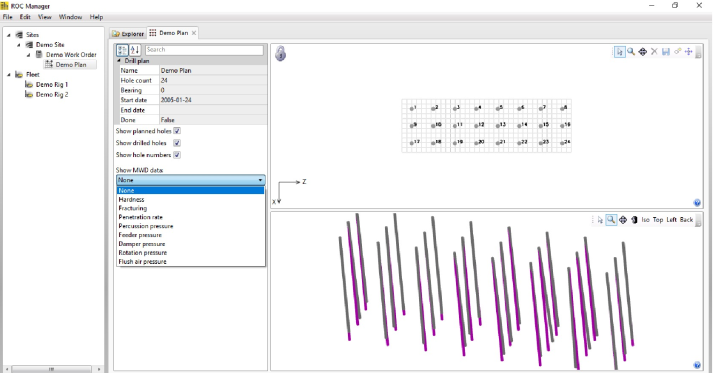

Roc manager software allow rock mass modelling from information gathered from surface manager. Ex. Penetration rates can be correlated to hardness in order to estimate waste to one ratios in blastholes.Certiq system

Certiq hardware mounted on the D65 transmits data gathered from the Rocma and Surface manager and alows user to view data in real time on Certiq portal

Diamond Core Drilling

Diamond Drilling is a form of core drilling which uses a rotary drill with a diamond drill bit attached in order to create precisely measured holes. As diamond is the hardest naturally occurring material in the world, it is ideal for creating openings in a range of materials including concrete, metal and glass.

Underground Drilling

Whether you’re developing a decline, drilling to break up ore or installing rock support, we engineer an extensive range of underground drill rigs for mining development and production.

Sandvik mining drill rigs are productive, reliable and economical

even in your most demanding production and face drilling applications.

Cover Drilling

- Exploration Drilling

- Fleet comprised of BoartLongyeardrill rigs

Reverse Feed Cylinder

- Feed is reversible to increase up-hole efficiency

- Automated Rod Handling

- Safer and easier rod handling

- High Torque Breakout

- Automated high torque break-out device of rods

- Fail Safe Rod Clamp

- Hydraulic open spring close rod clamp for fail safe rod handling

- Direct Coupled Feed Frame

- Direct coupled feed frame results in lower maintenance and smoother feed transmission.

- Modular Design

- Easier handling for unground moving and machine upgrades

- Electric Hydraulic

- High torque drill head, 150kn feed frame with very low noiseexposure (<50db)

- The LM30 has improved safety with a remote control panel allowing for remote rig operation at a safe distance.

- The LM30 SS is capable of drilling at various angles fromvertically downward to vertical upward at B, N and H sizes at depths of 310m, 180m and 80m respectively.

- The LM30 SS drill unit is compact, mobile and self-driven drill allowing for rapid setup.

Blast Hole drilling

We provide good drilling practices include carefully monitoring drill-rig operating parameters, taking careful notes of the changes in geology during drilling and effectively communicating to the blasting crew any unusual conditions encountered during drilling that may affect blasting results.

Automatic rod handling and carousel makes efficient system for blasthole or grade control drilling.

Air Core Drilling

Air-Core Drilling uses steel or tungsten blades to bore a hole into unconsolidated ground. The drill cuttings are removed by the injection of compressed air into the hole. Aircore drilling is an ideal method for obtaining good core recoveries from old tailings and slimes dams;

The method utilizes airflow similar to RC drilling but employs a rotary drilling action to produce core.

Mud Rotary Drilling

Mud rotary drilling is an excellent technique for the environmental industry to install groundwater monitoring wells. It will allow you to install monitor wells in the shortest amount of time. It also allows you to achieve superior penetration rates in very hard geological formations.

Master Drilling Exploration utilizes mud rotary drilling chiefly during construction of large diameter 18” + aquifer production holes.

Sonic Drilling

Sonic technology is ideal for both deep and shallow drilling applications where undisturbed core sampling through almost any type of geological formation is required. This powerful technology provides many advantages over other types of drilling techniques. It is a low impact technology that is safer by minimizing crew tool handling. By rotating and vibrating the rod, core barrel, and casing at sonic frequencies a clean borehole is drilled, cored and cased at the same time.

Master Drilling provides sonic drilling services and is experienced in drilling sand and semi consolidates formation as well as in the heavy mineral sand’s environment.